Precision, innovation and quality

We have developed our manufacturing experience by specialising in projects for the furniture industry, but we are able to assist wherever plastic components are needed. For several years we have also successfully carried out projects for industries other than furniture, supplying injection moulding and extrusion products. Having agreed commercial terms and made the tools, we can become a partner for any production that uses plastic components.

projects from other

business areas

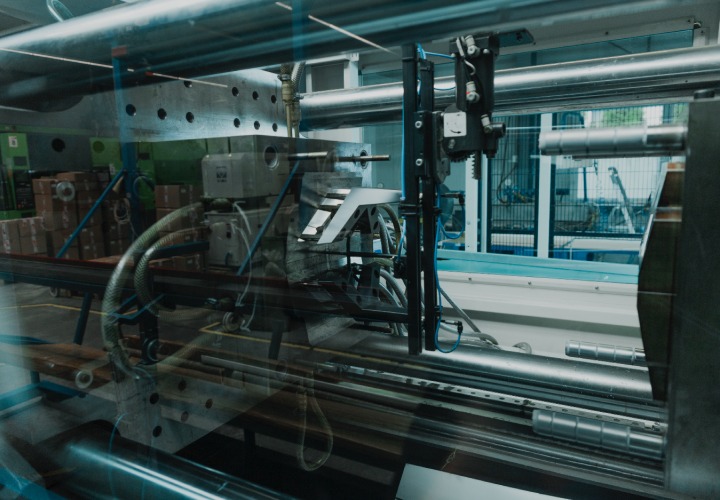

Injection moulding

We are the expert in injection moulding. Our state-of-the-art machinery offers a wide range of production possibilities and our multi-batch production guarantees fast and reproducible order processing. We also specialise in plastics that have special requirements, such as a high degree of non-flammability or transparent raw materials.

Extrusion

Due to our own plastic profile extrusion lines, we have become a leader in the production of furniture accessories by extrusion. Our products reflect the latest trends and meet individual designer expectations.

Manual processing

We guarantee that our products undergo the entire machining process to the highest quality standards. The flexibility of the production line makes it possible to precisely drill holes and individually adjust the length of the extruded parts.

Colours and decors

We offer a wide range of foils and lacquers specifically for handles, profiles and furniture legs. On agreement, our customers can adjust the decoration technique to their needs, choose the colour of the dye or individually match the foil to the original furniture board. We can offer spray-painted products in any RAL colour, vacuum metallized, dyed in the mass at the production stage or foiled. We also have our own pad printing decoration line.

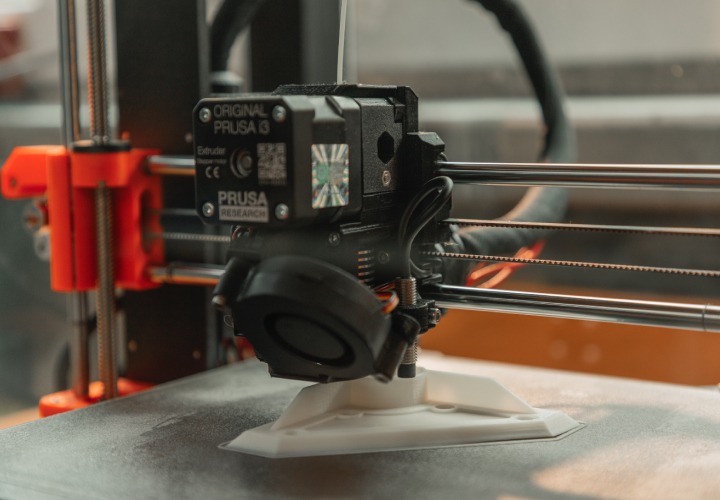

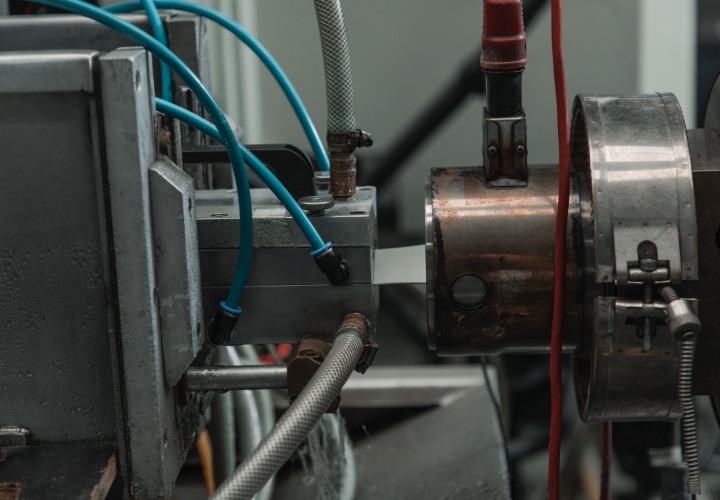

Tool-Room

We own the moulding and CNC centres. Our own tool room ensures the safety of the production process and reduces the lead time for new products. We produce prototypes using the 3D printing method, which shortens the path from the idea to the creation of the first prototype. Our in-house moulding centres (CNC machines), enable us to precisely mill the shape of selected profiles in accordance with our customers’ specifications.